Rapid-sorb® dispersion tube system

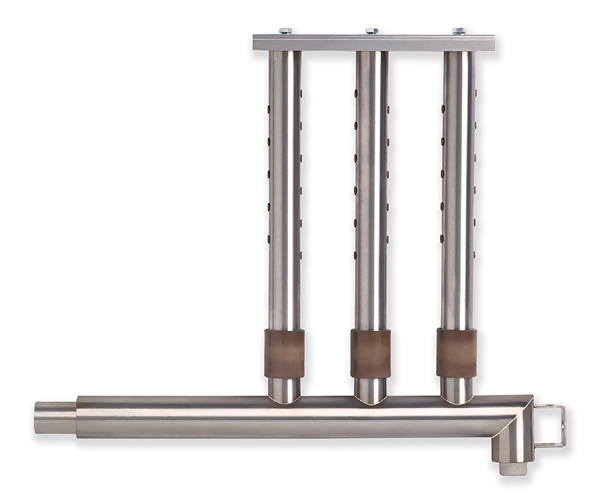

Rapid-sorb® dispersion tube systemNONPRESSURIZED STEAM DISPERSION

Rapid-sorb® dispersion tube system

Single header with multiple tubes, short non-wetting distanceRapid-sorb steam dispersion tube systems are designed for applications where multiple tubes are needed to handle the load and/or when the available non-wetting distance is limited.

Capacity: Up to 955 kg/h

- Short non-wetting distance, compared to single dispersion tube

- Models available in sizes from 254mm x 254mm

- For horizontal or vertical airflows with header inside or outside duct

- Available with High-Efficiency Dispersion Tubes

Single dispersion tube

Installation flexibility

- Low-capacity dispersion for horizontal or vertical airflows

- Available as a High-Efficiency Dispersion Tube

Capacity: Up to 44.1 kg/h

PRESSURIZED STEAM INJECTION OR NONPRESSURIZED STEAM DISPERSION

Ultra-sorb steam dispersion panel

The Ultra-sorb steam dispersion panel established industry standards for meeting short non-wetting requirements.- Guaranteed non-wetting distances

- Lowest installation cost

- Reduce wasted energy with High-Efficiency Tubes

- Models available from 305 x 305 mm to 3658 x 3658 mm

- Factory assembled for easy installation or shipped unassembled

- Requires lee than 7kPa of pressure to disperse steam

Ultra-sorb XV

Highest performance

Ultra-sorb dispersion tube system

Ultra-sorb dispersion tube system- Highest performing steam dispersion product on the market

- Lowest heat gain

- High-Efficiency tubes

- Zero water waste – vaporizes generated condensate and returns pressurized condensate

- For pressurized steam applications, 35 kPa minimum

- Chemical-free boiler steam humidification when used with STS steam to steam humidifier

Capacity:

Pressurized steam: Up to 898 kg/hr

STS Humidifier: Up to 204 kg/h per panel

Ultra-sorb LV & LH

Most versatile

- Optional High-Efficiency tubes

- Easy Installation

- For pressurized or nonpressurized steam applications

Capacity:

Pressurized steam: Up to 1815 kg/hr